VerSo

Sales Operations Portal

Introduction

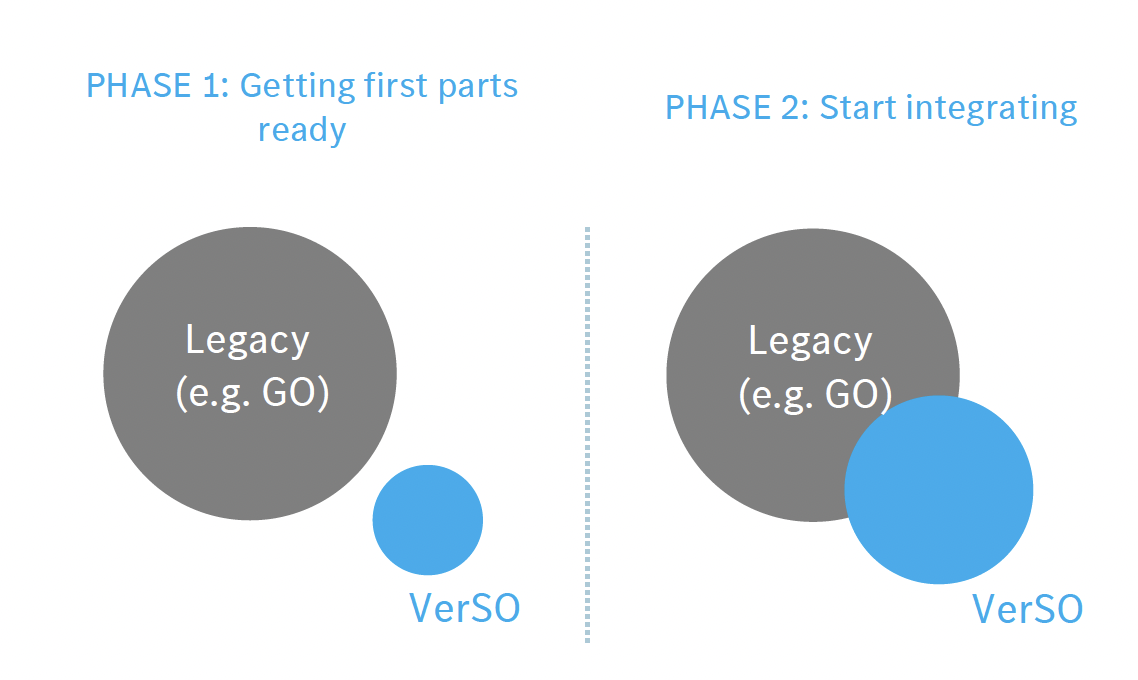

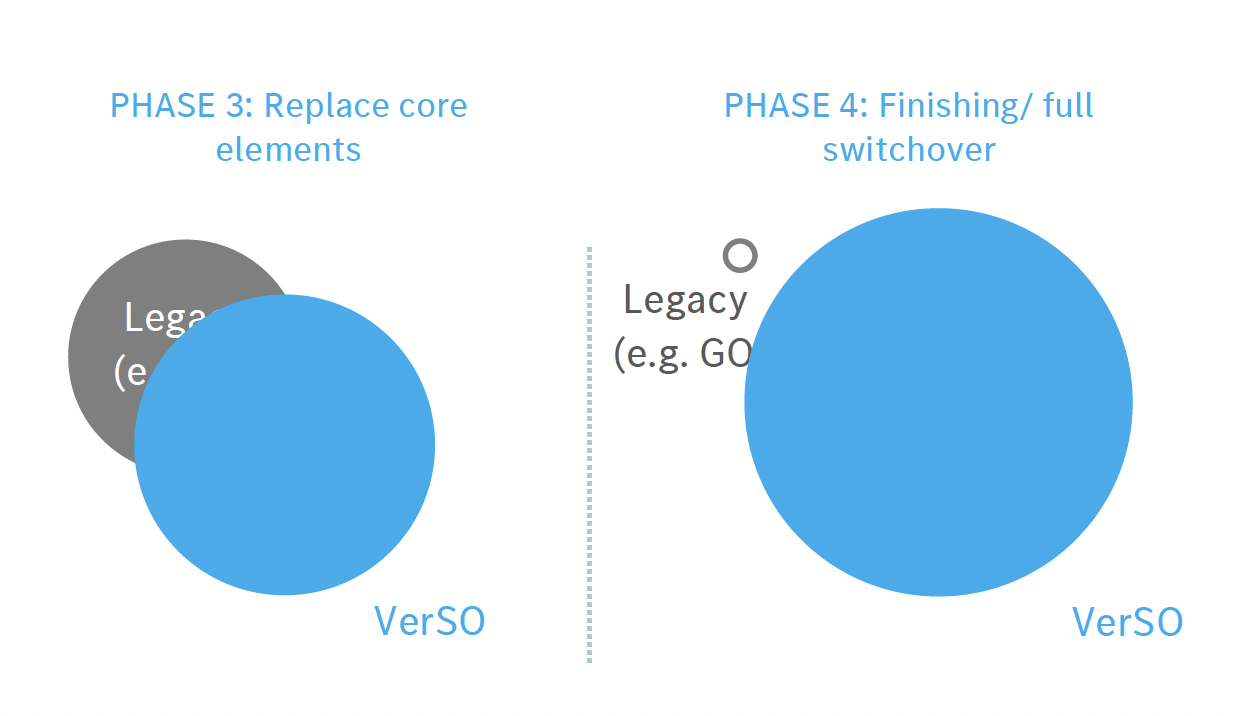

Mercedes-Benz is reimagining the future of vehicle ordering through a bold global initiative called Verso—a unified internal platform aimed at transforming the entire sales experience. Currently hindered by a complex chain of intermediaries, manual steps, and long lead times, the process is prone to delays and costly errors. Verso is designed to eliminate those inefficiencies by enabling customers to directly configure and order their vehicles—without friction, without error, and without middle parties.

From the moment a car leaves the factory to the moment it reaches the customer, Verso aims to provide full transparency, tracking, and automation. By tightening every step of the ordering and delivery chain, the platform seeks to shorten lead times significantly, reduce order mistakes, and speed up the arrival of customized vehicles. It’s a streamlined, global solution intended to bring overnight vehicle sales and seamless fulfilment into reality—wherever Mercedes operates.

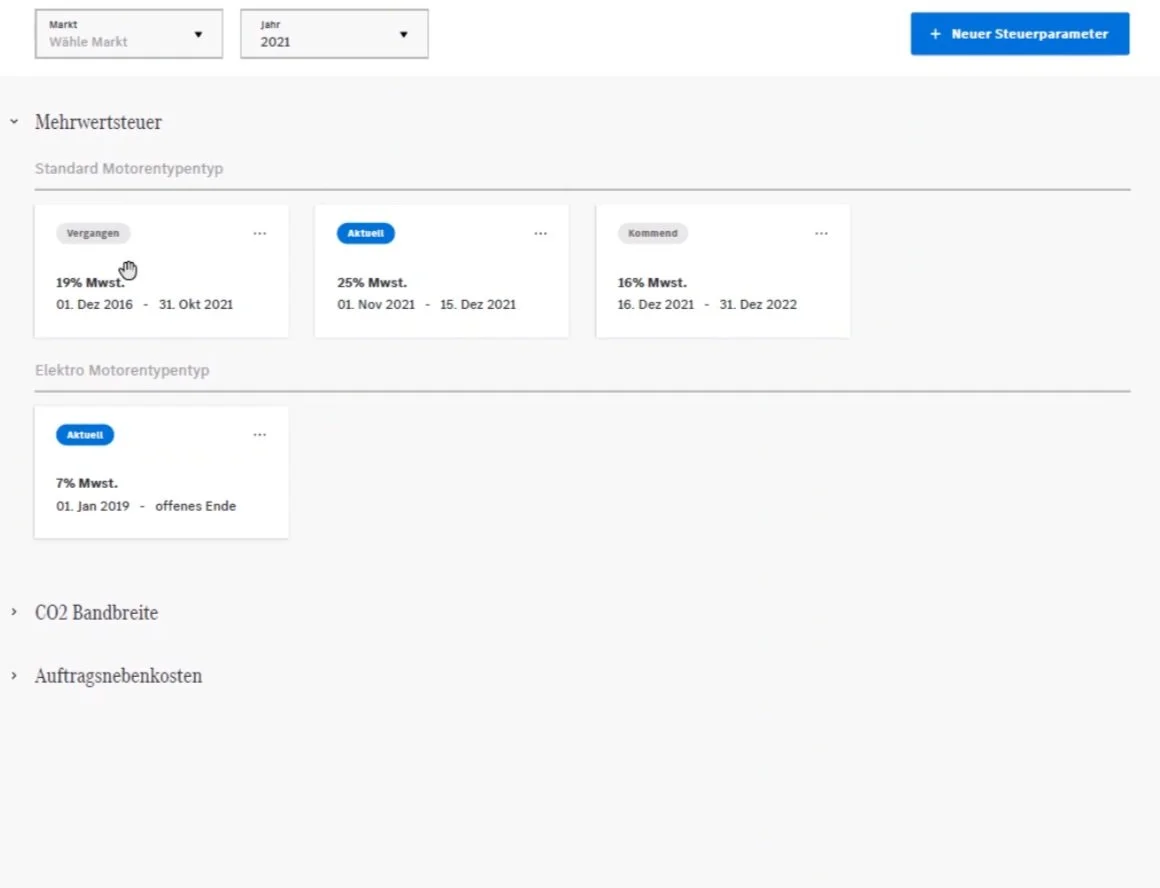

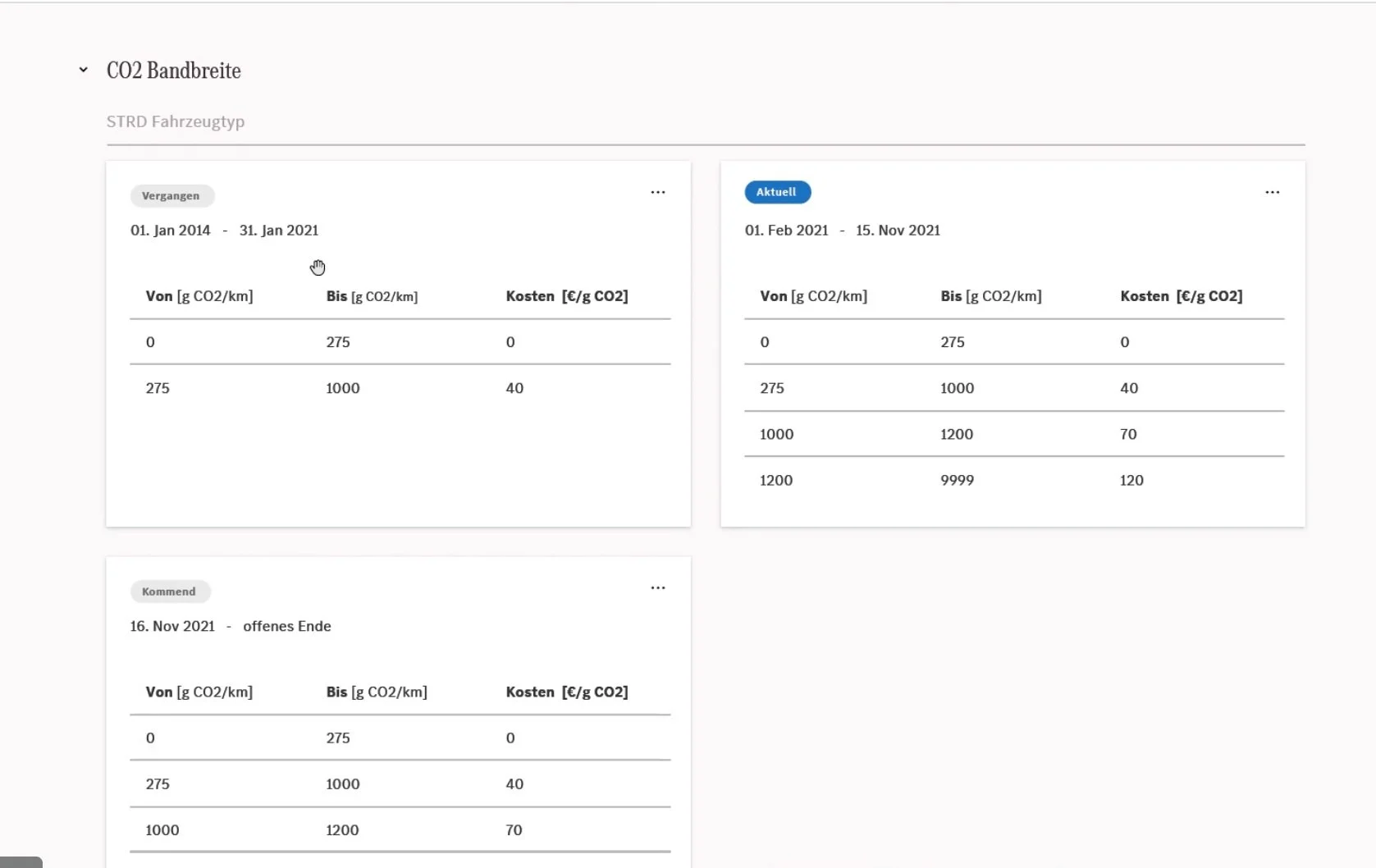

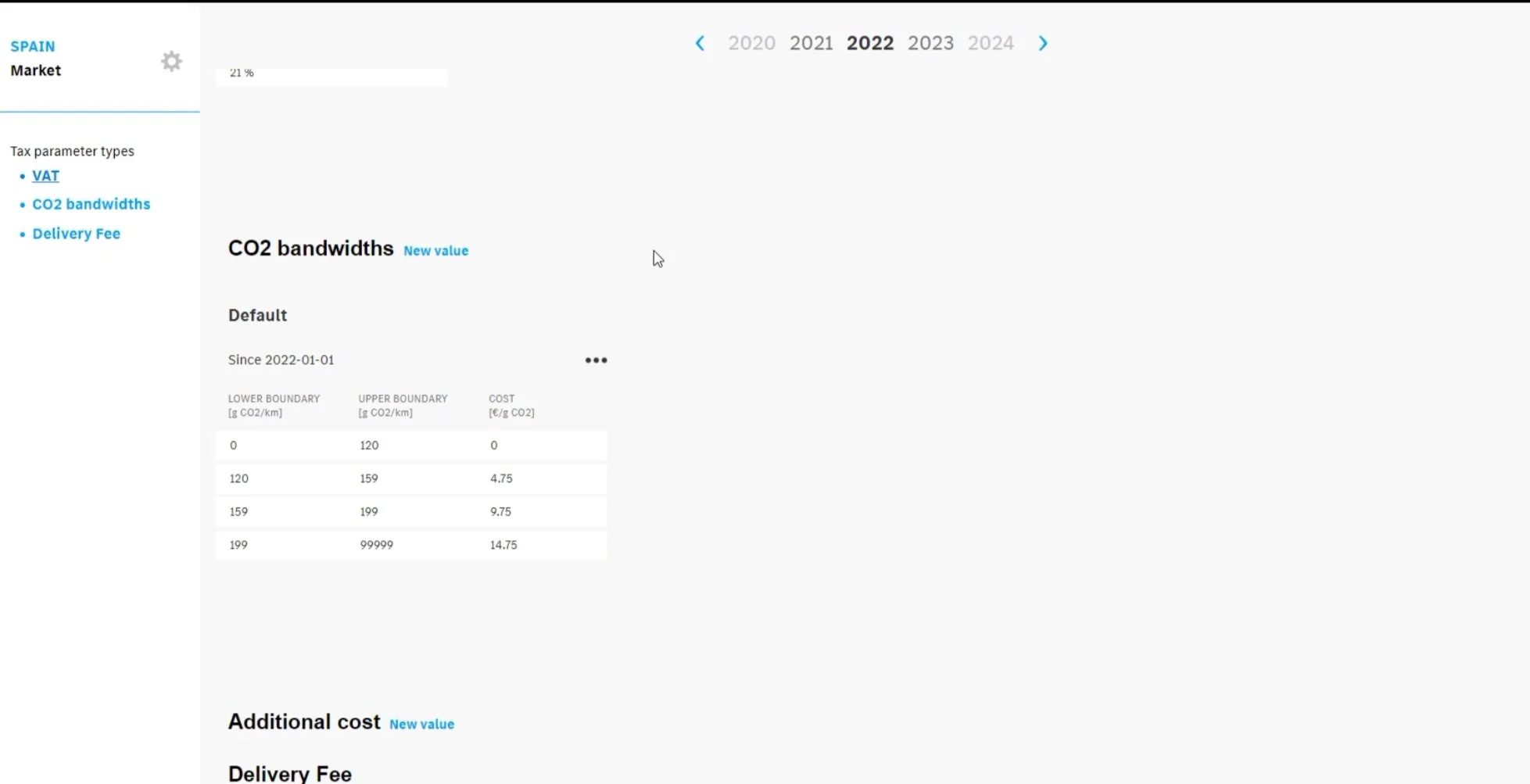

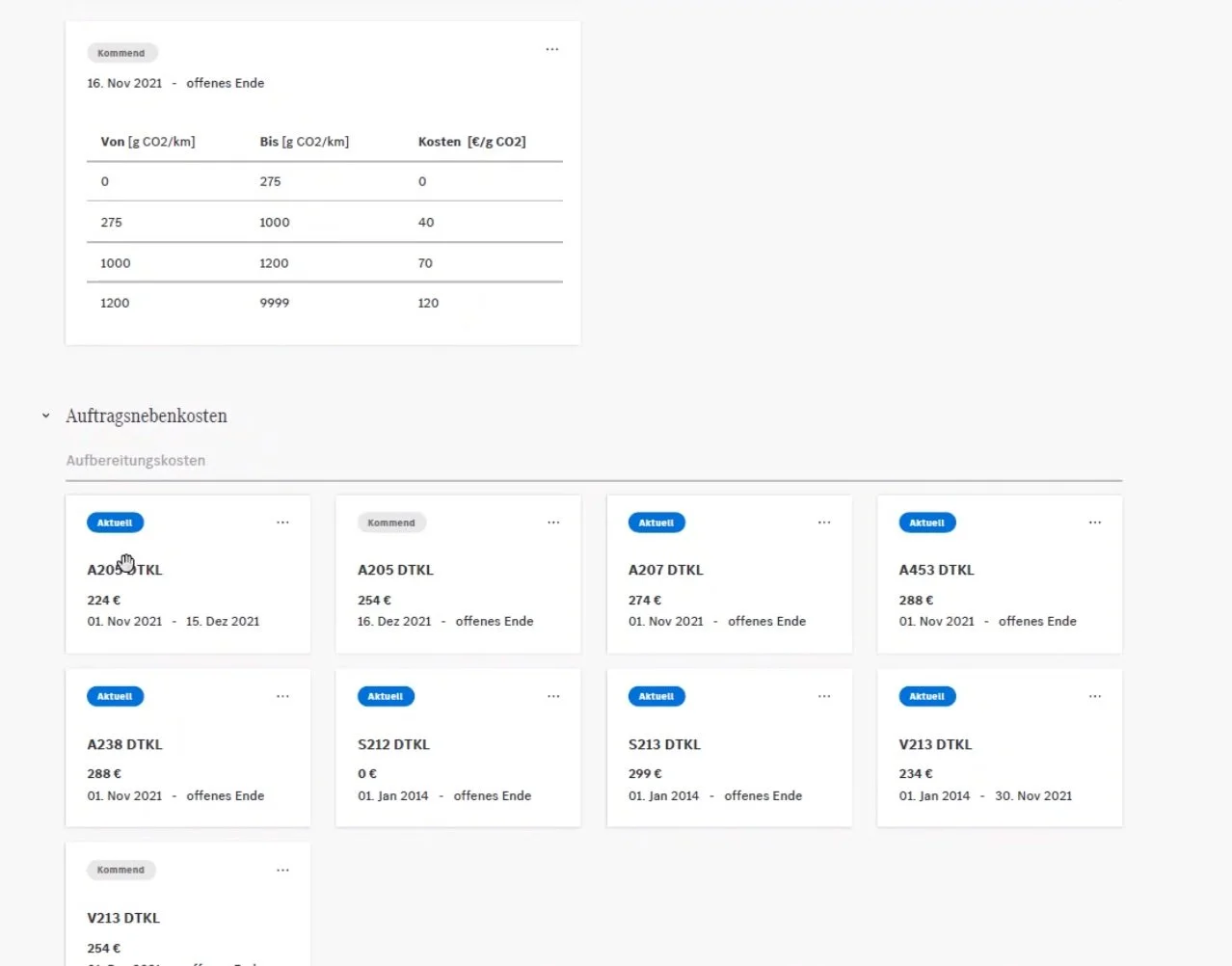

Tax

This section showcases the early-stage development of the tax parameter management tool within the Verso platform, which was initially piloted for deployment in the German market. As Germany operates under very specific and detailed taxation rules for vehicles—including CO₂ emissions-based costs, VAT, and delivery fees—it served as an ideal testbed to validate the logic and usability of the system before considering a broader global rollout. The plan was to first implement and fine-tune this tool locally, then expand its structure and capabilities across all other Mercedes-Benz markets worldwide

This section showcases the early-stage development of the tax parameter management tool within the Verso platform, which was initially piloted for deployment in the German market. As Germany operates under very specific and detailed taxation rules for vehicles—including CO₂ emissions-based costs, VAT, and delivery fees—it served as an ideal testbed to validate the logic and usability of the system before considering a broader global rollout. The plan was to first implement and fine-tune this tool locally, then expand its structure and capabilities across all other Mercedes-Benz markets worldwide

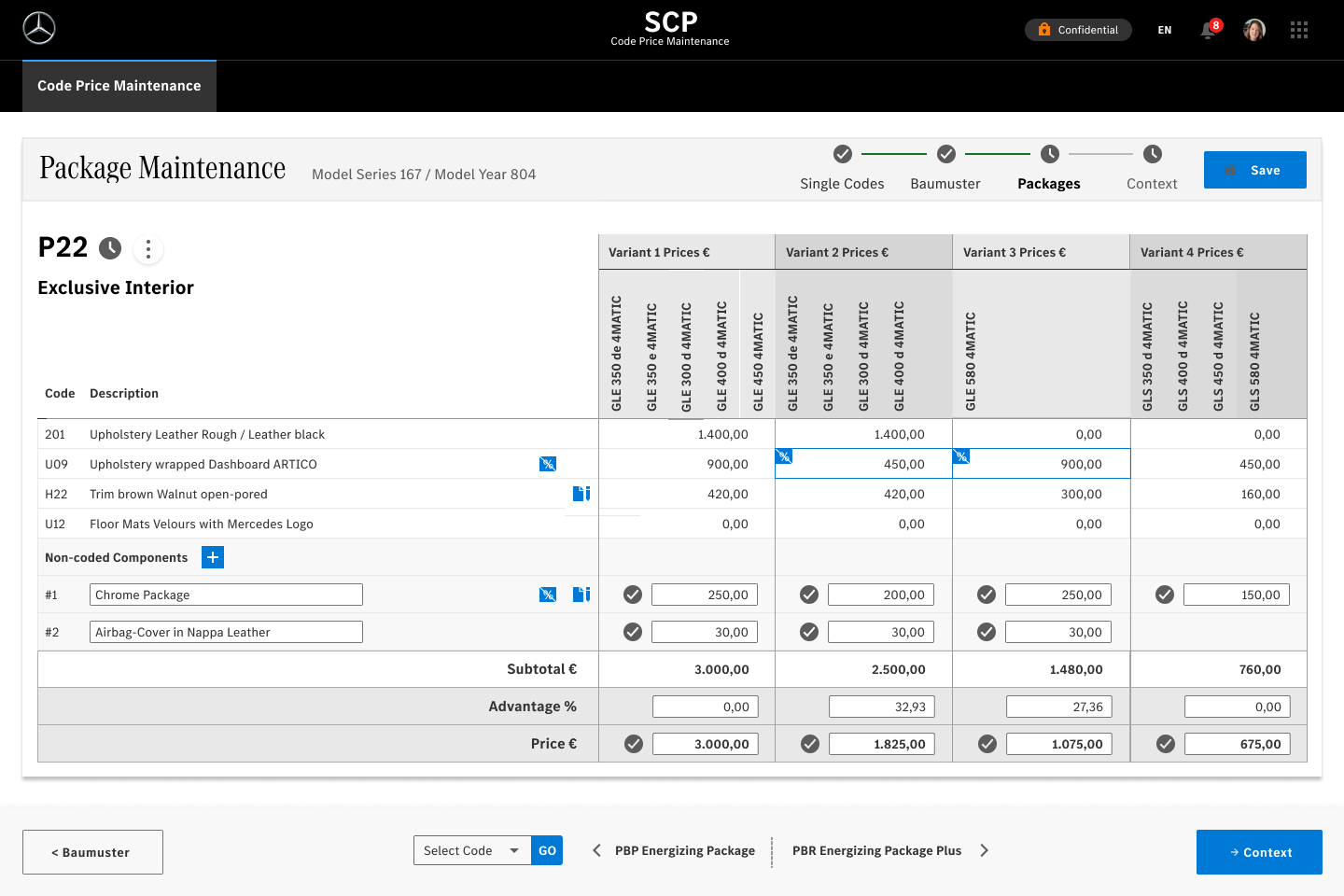

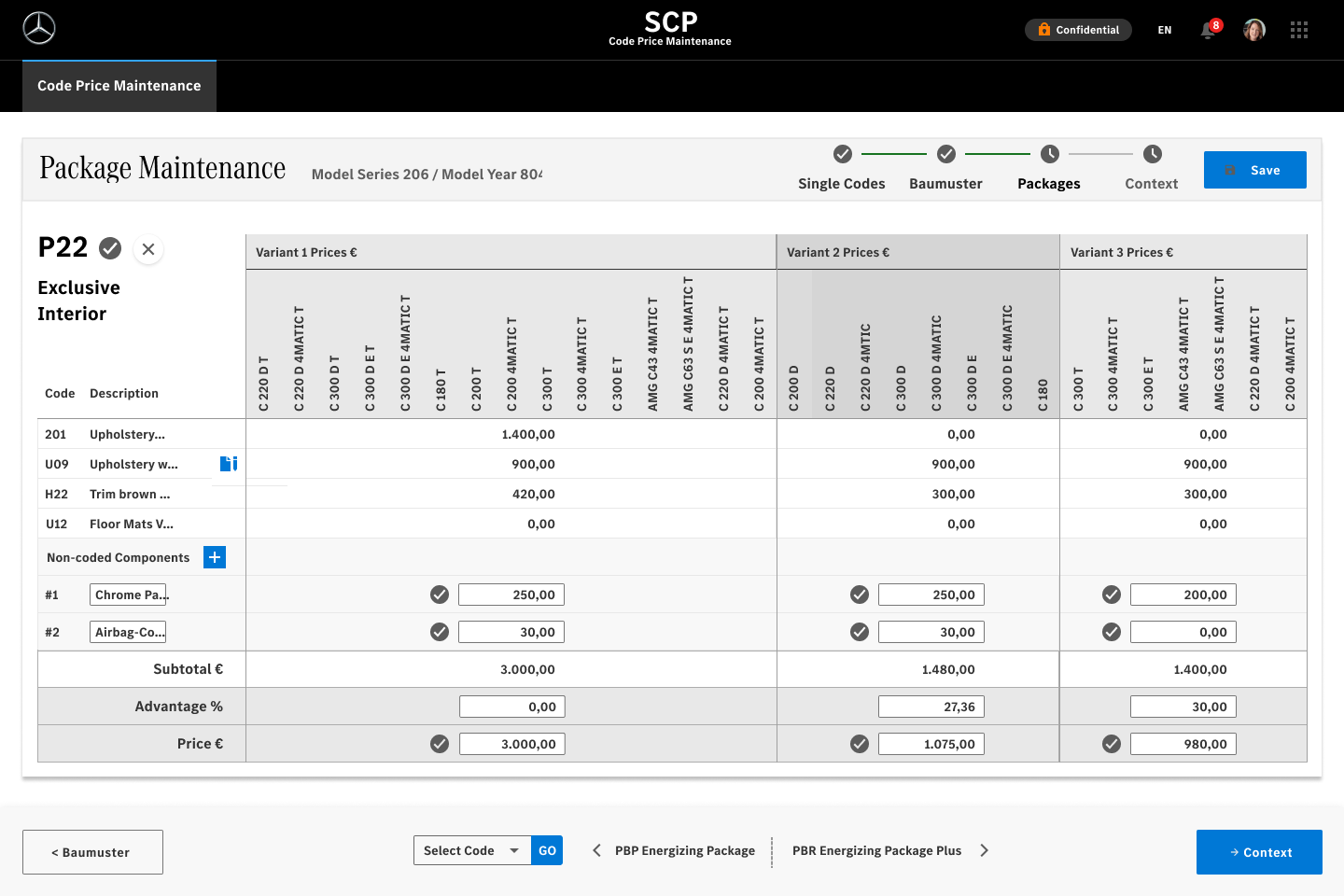

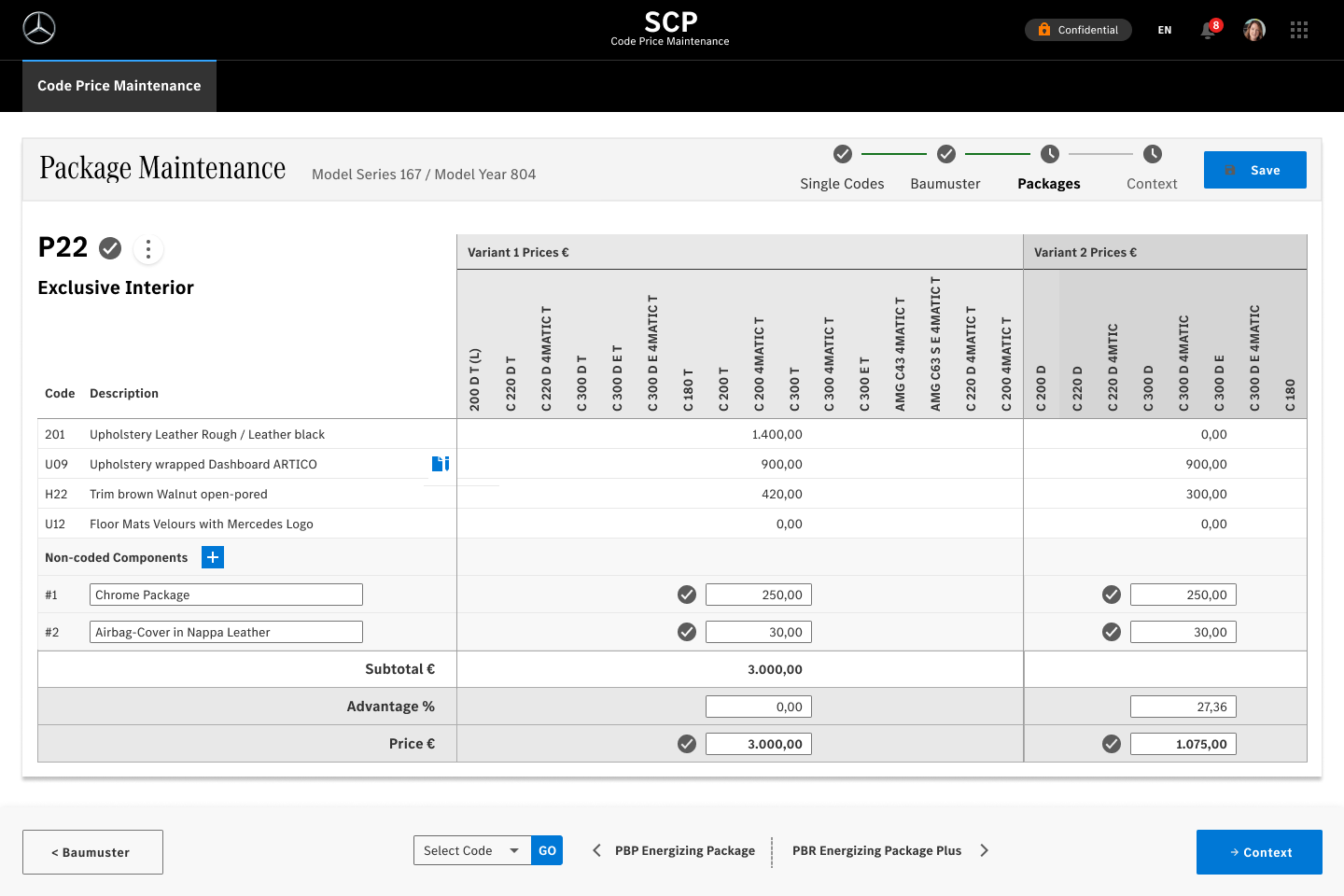

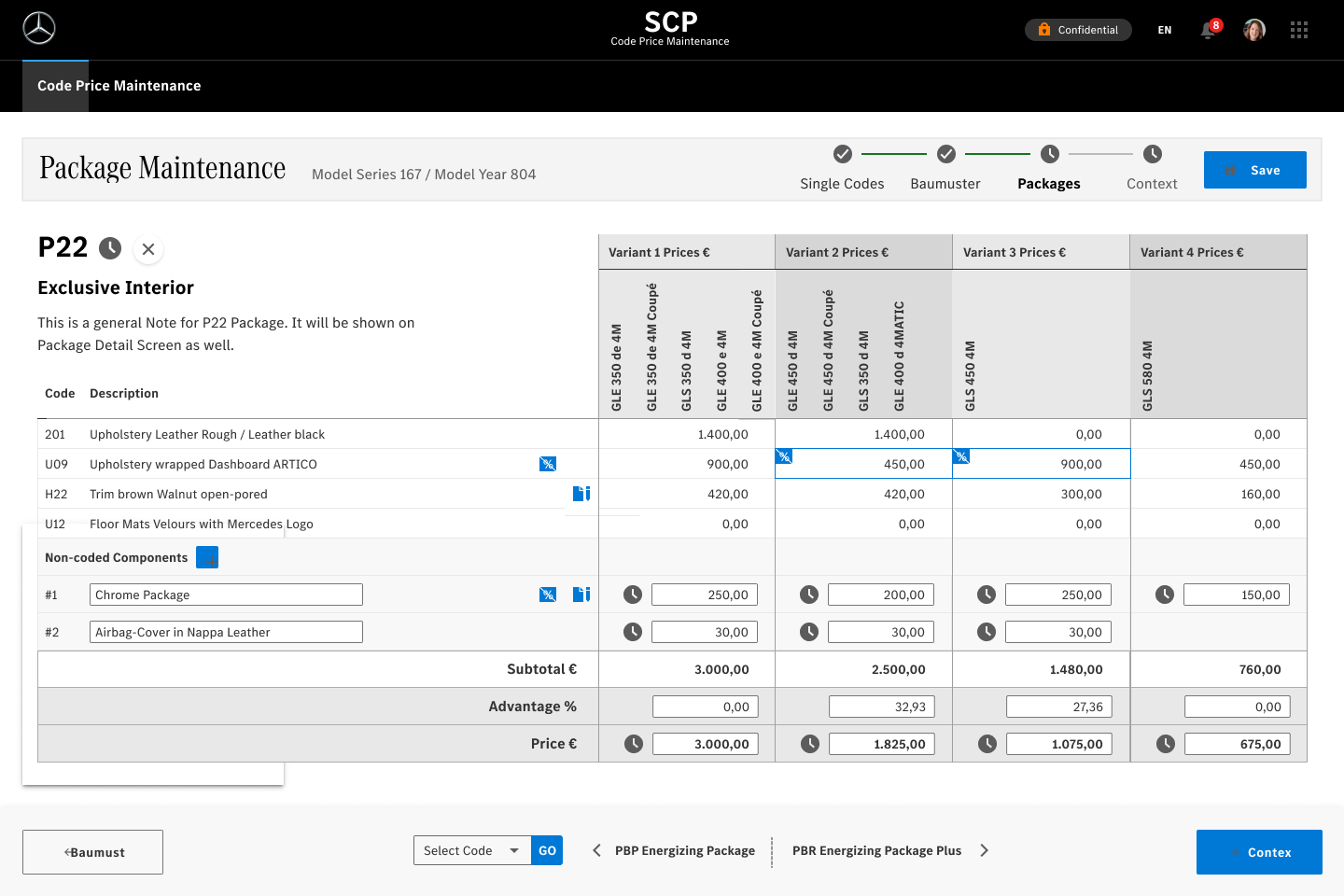

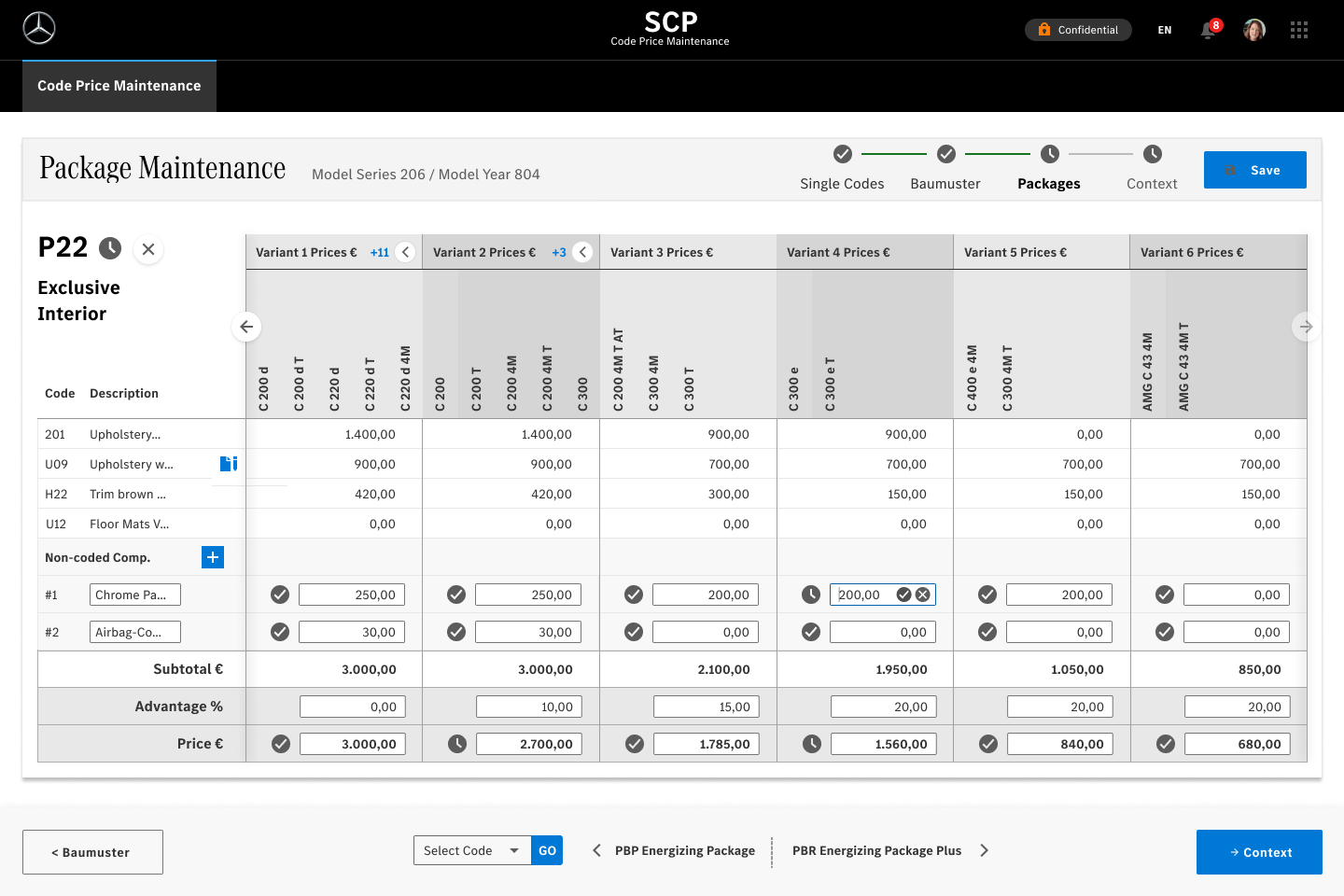

These PRC (Price Creation) screens show a highly detailed internal tool that supports Mercedes-Benz teams in maintaining and updating package pricing data across various car models and variants. Each screen represents a different stage in editing or checking how specific features or packages—such as interior materials or add-ons—are priced across vehicle variants for a given model year. The interface allows for cross-referencing and batch editing of pricing information, ensuring consistency and transparency across multiple markets. Our goal here is to create a clear, structured experience where users can accurately adjust pricing with reduced friction and minimal risk of error, especially during the critical process of launching or updating new vehicle models.

SLS

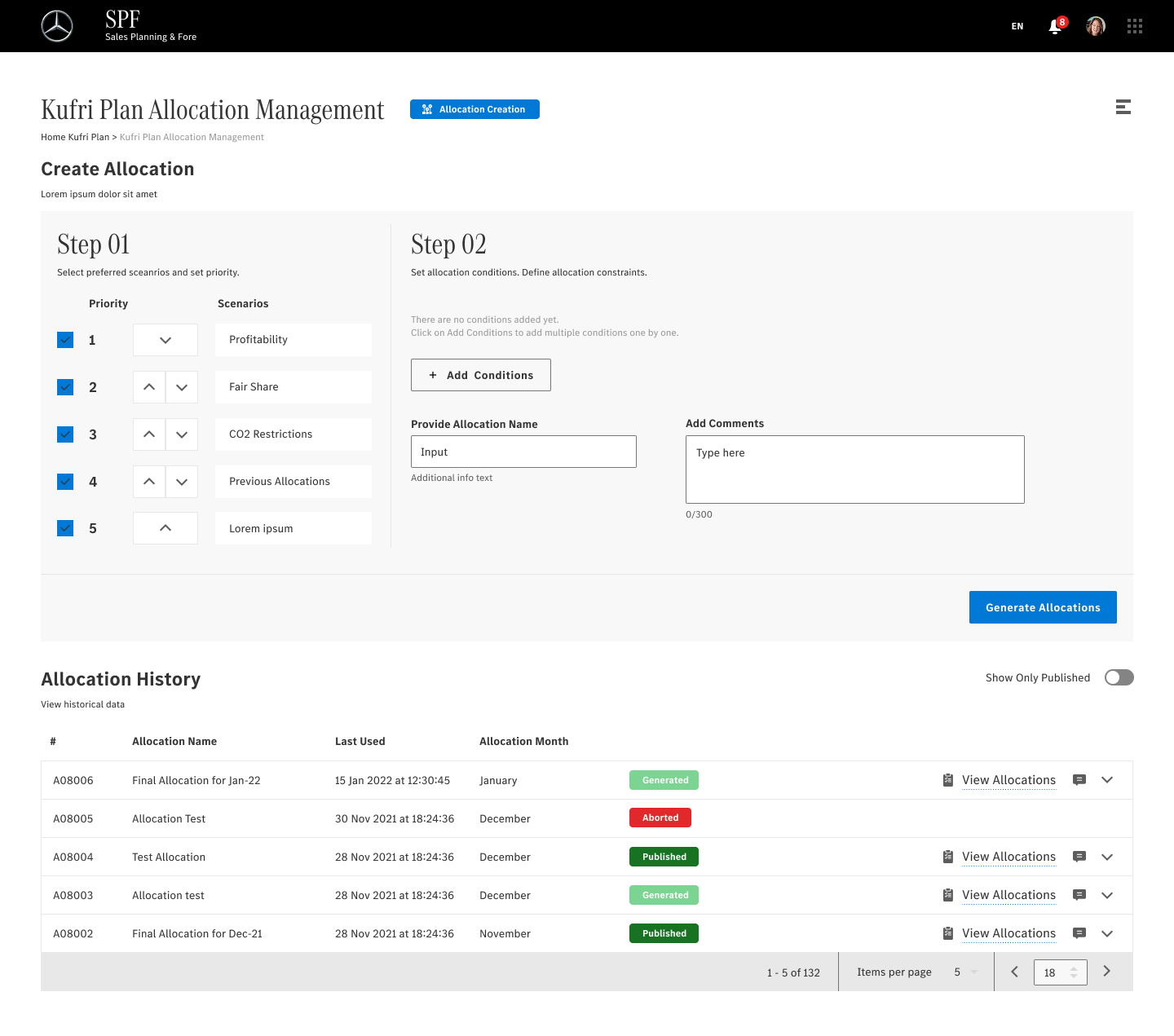

Kufri Customer Allocation Planning

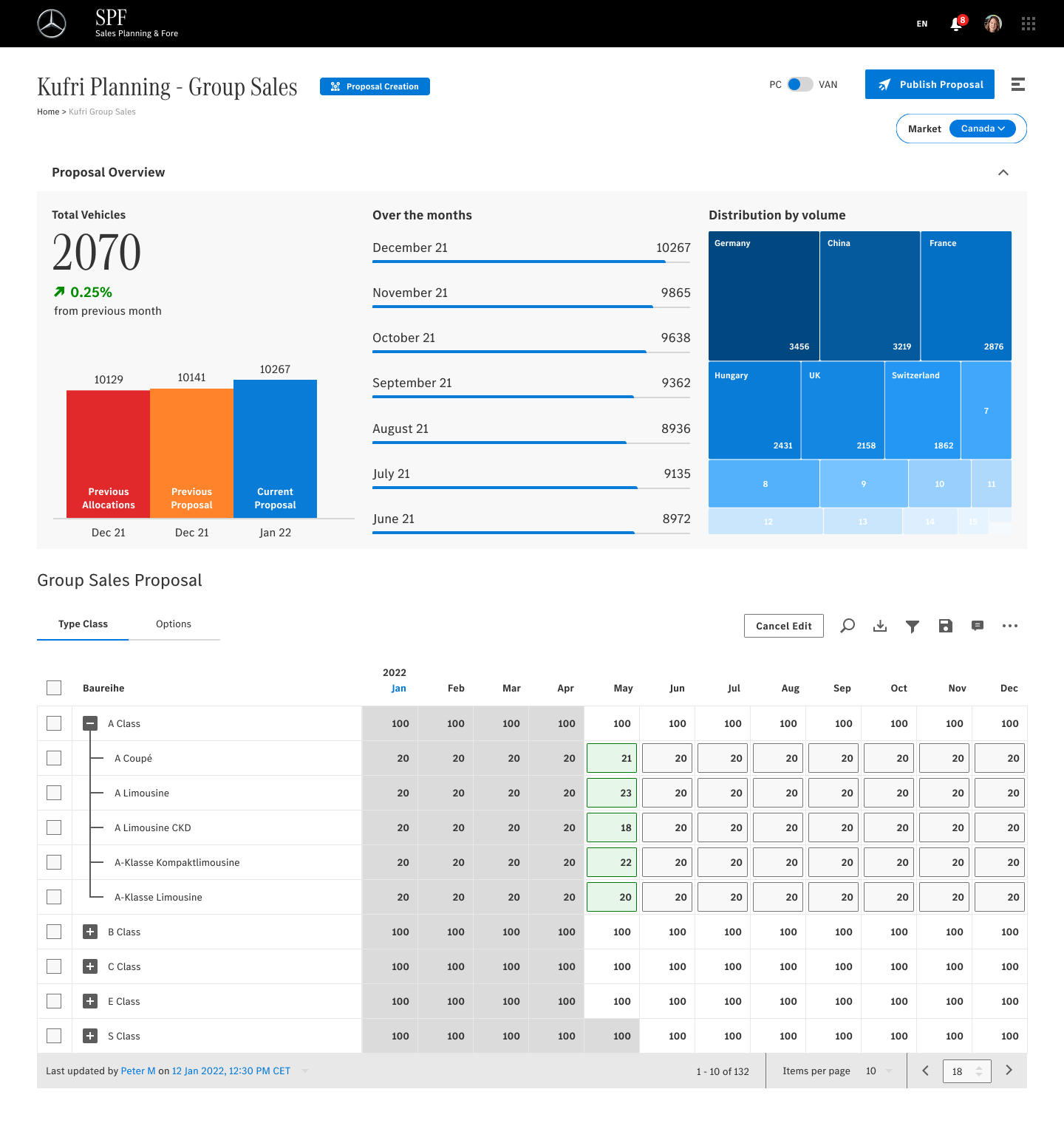

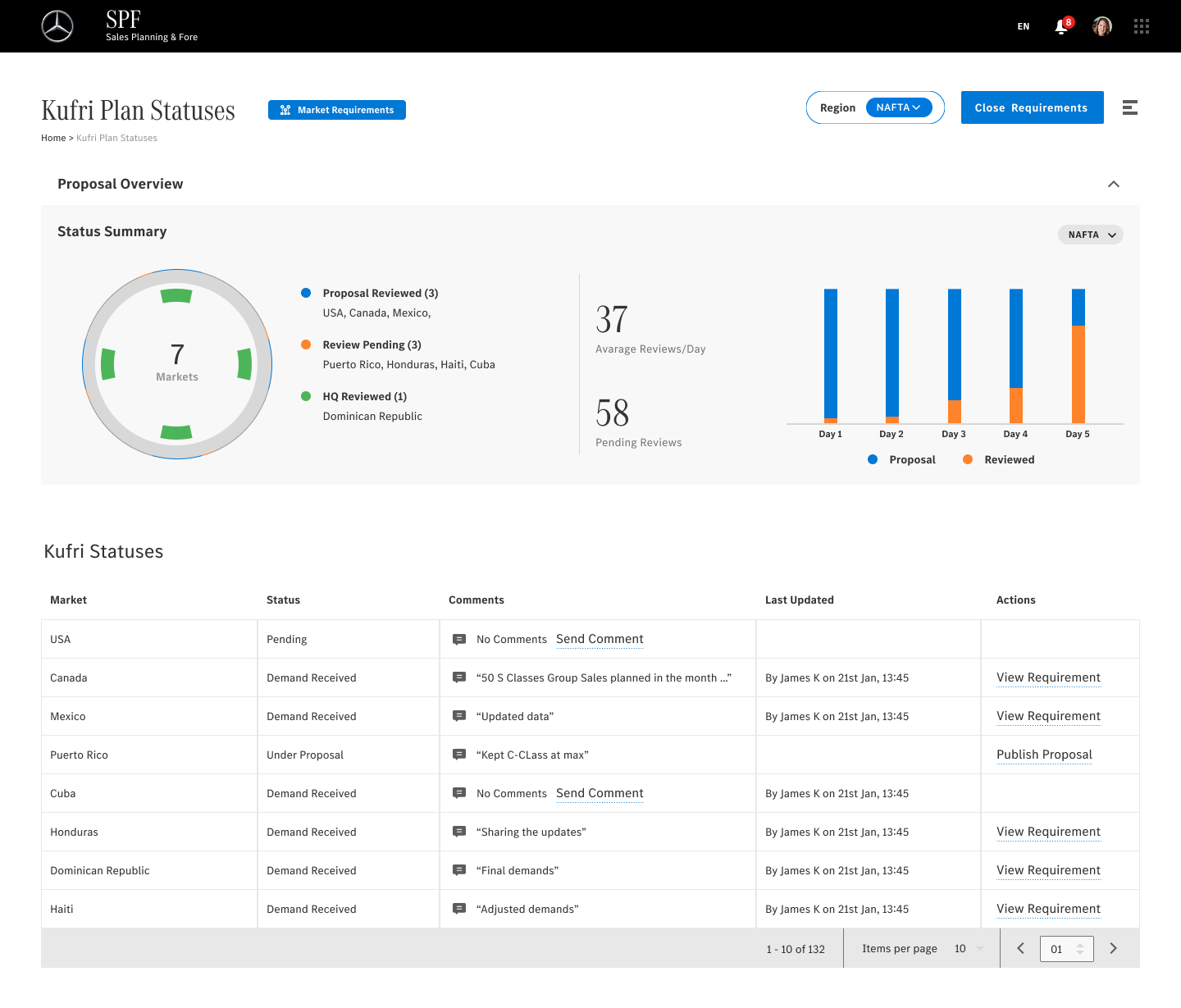

KUFRI (Customer Allocation Planning) supports strategic vehicle allocation and distribution planning across global markets. The platform enables business planners to configure and prioritize allocation methods such as profitability, fair share, and sales performance—each scenario offering a different logic for how vehicles are split across markets. Users create and name allocation plans, define conditions, and maintain a full allocation history, reinforcing transparency and consistency in the decision-making process.

These dashboards summarize total vehicle proposals and visualize production requirements, plant capacity, and allocation breakdowns by region and volume. The system manages the full lifecycle of a proposal—from initial configuration and internal review to final publishing across specific markets such as the USA or Canada—while offering real-time updates, in-context commenting, and adjustment options. The status overview keeps all stakeholders aligned by tracking pending reviews and proposal statuses across regions, helping to surface bottlenecks and drive coordinated actions. Rather than a single feature, KUFRI functions as a modular, data-driven ecosystem that connects market demand with production planning in a clear, auditable, and efficient way.

PRC

Vehicle Price creation

& Package

Maintenance

Next Steps

As the product reaches maturity, the design system is now consistently applied, and repetitive journeys across swim lanes have been unified for coherence and efficiency. Component usage is continuously optimized through close collaboration and regular tracking between developers and designers. With its core structure now stable, the platform is scheduled for deployment in additional markets—beginning with Spain and China—following the earlier launch in Germany. Mercedes-Benz confirms the shift to Model D, eliminating local and international dealers to create a fully centralized, digital-first vehicle ordering experience.

Strategy

Our strategy involved iterating multiple hero page layouts to identify which messaging and visuals resonated most with new, interested customers. We conducted A/B testing across these variations, focusing on headline clarity, call-to-action placement, and the integration of trust-building elements like testimonials and data snapshots. Once the individual products reached a level of maturity—having been thoroughly tested, deployed to AWS, and validated by developers for data integration and functionality—cross-cluster collaboration became essential. Weekly UX Guild meetings were established to facilitate alignment, encourage knowledge sharing across domains, and gradually develop a unified Verso Design System grounded in technical scalability and UX consistency.

Reflection/

Thoughts

The product takes significantly longer to develop than initially planned. With numerous teams spread across different global locations, it is difficult to establish a centralized communication workflow that ensures consistent participation and alignment. The evolving business goals and shifting roadmaps often result in paused features or halted development, delaying progress. In several instances, UX considerations are deprioritized in favor of quickly launching a functional tool that can begin generating value. While the foundation is now solid, future phases benefit from revisiting the UX layer—allowing thoughtful refinement and pattern consistency. At this stage, the platform feels more like a rushed MVP than a fully realized user-first experience, but it is well positioned for steady improvements over time. One of the clusters is specifically designed to support continuous user engagement, meaning that once the platform is deployed across all business roles, users are able to raise questions, offer feedback, request support, and participate in sporadic testing—ensuring UX refinements evolve in parallel with live product use.

The Challenge

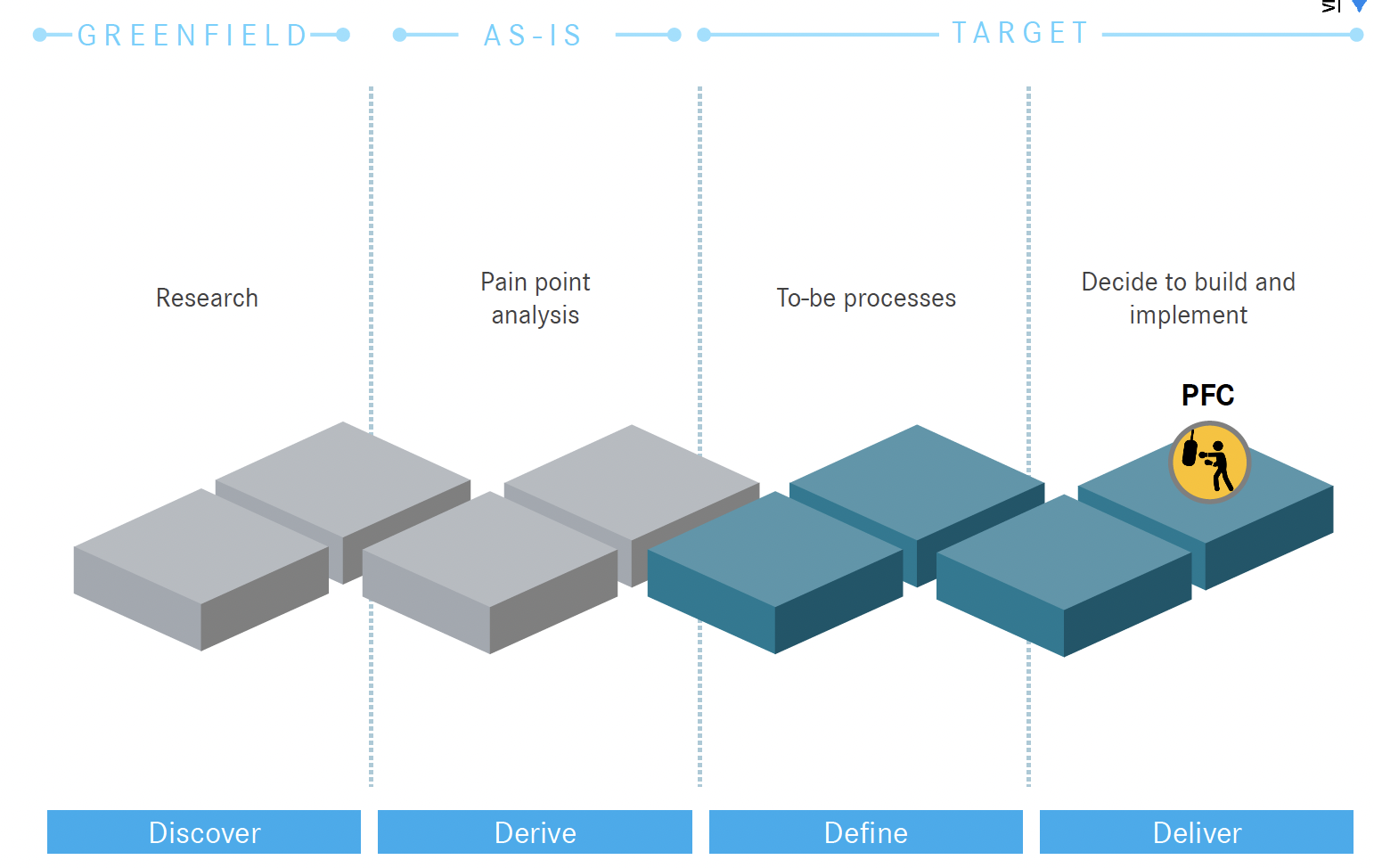

Establishing a Global Business User Ecosystem One of the first major challenges in building Verso is defining the internal business ecosystem across Mercedes-Benz HQ and its global markets. To ensure the platform reflects real-world workflows, we need to map out the roles of business users involved in the vehicle ordering process—from pricing analysts to logistics coordinators. These user roles are then grouped into functional clusters, giving structure to how internal processes are mirrored inside the platform.

Dividing Clusters and Reuniting the Product Once clusters like SCP and SLS are established, each one is assigned to its own dedicated product and UX team responsible for building core functionalities. However, as development progresses independently, one of the critical challenges is ensuring the platform doesn’t splinter into disconnected modules. Our focus later shifts to unifying the design system and bridging functional gaps between clusters—so the end-user experience is seamless and the system operates as a cohesive whole.